TGV (Through Glass Via) Fabrication

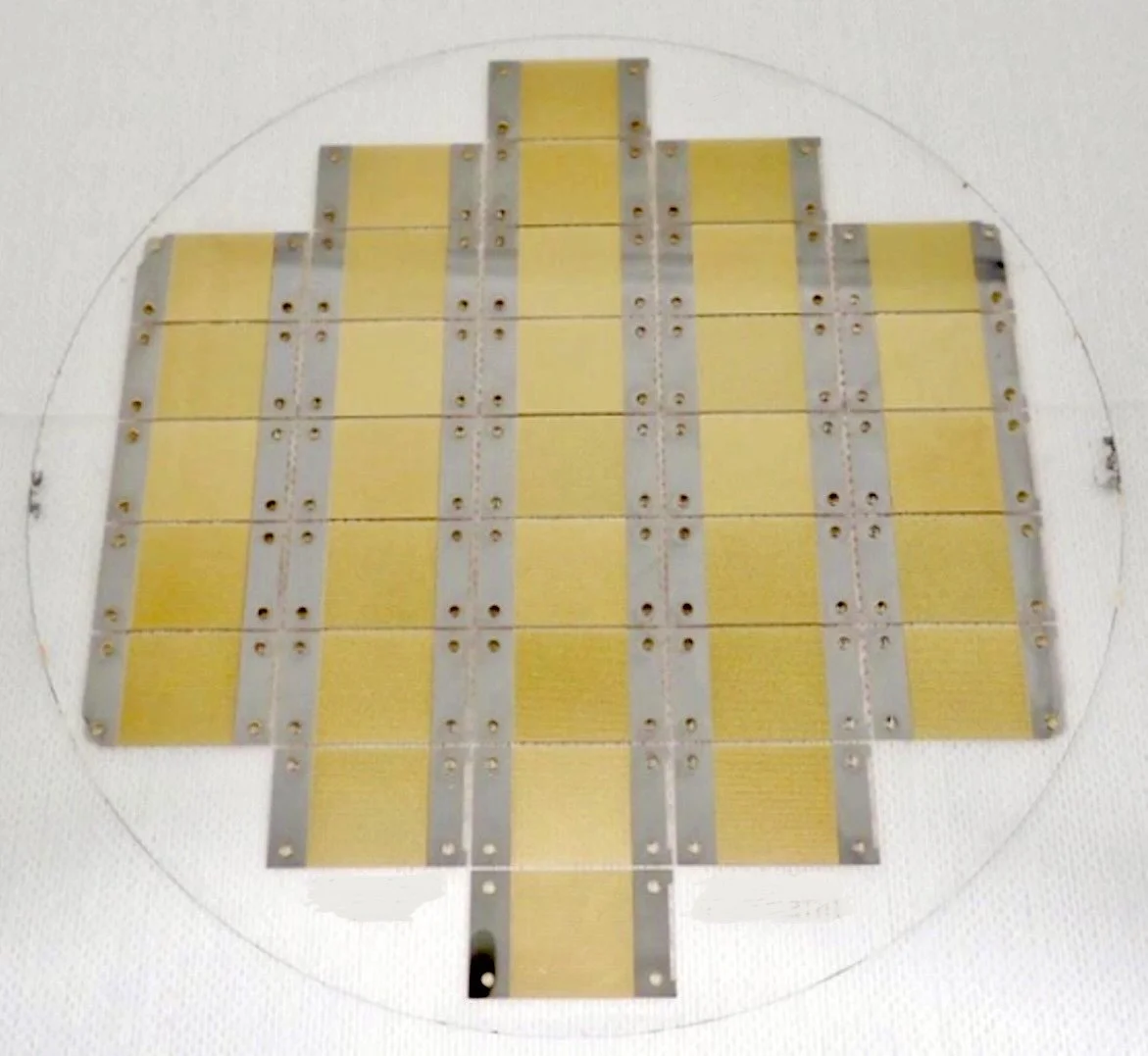

Glass interposer chips on wafer

TGVs can play an important role in cost-effective advanced wafer packaging (2.5D&3D).

Glass has below advantages over silicon

High resistivity

Low electrical loss

Adjustable CTE (Better CTE match with organic package substrate than Silicon)

Low-frequency loss for RF applications (Low-loss tangent)

Optical Transparency

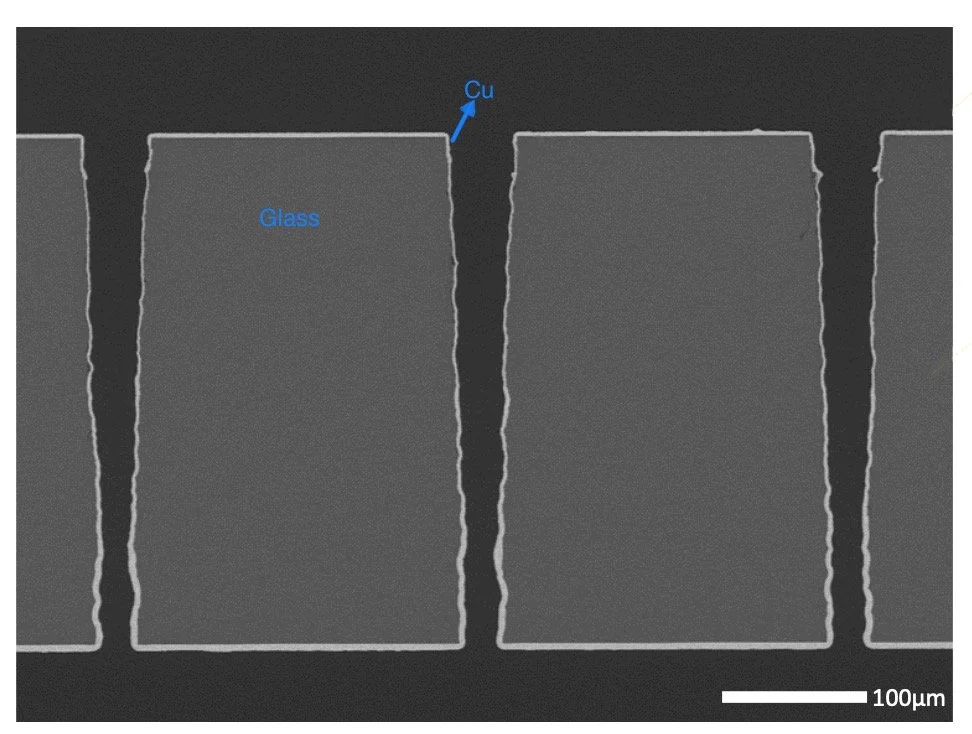

Conformal Cu via

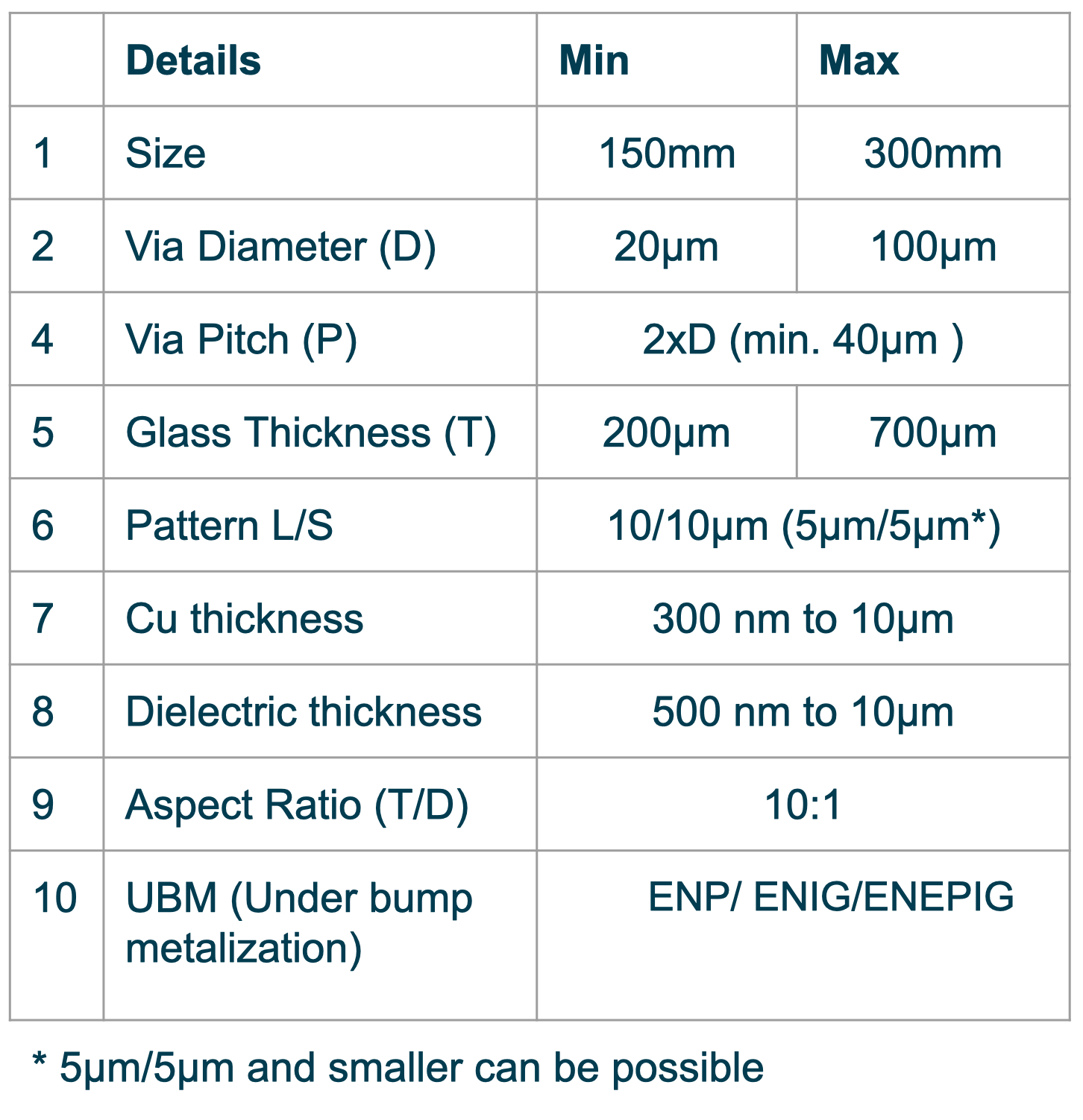

We offer advanced TGV (Through Glass Via) microfabrication with

Precision diameters

Achieve diameters as small as 20µm

Capability to incorporate vias of varying diameters on the same substrate

Different diameters on opposite sides of the substrate are possible. (e.g., 30µm on one side and 60µm on the other).

Versatile Via Shapes:

Accommodates different via shapes based on diameter requirements, including hourglass, straight, and tapered designs

Substrate Size Flexibility:

Ranges from standard wafer sizes (100mm, 200mm, 300mm) to larger panel sizes (up to approximately 510x510mm)

Diverse glass types

Borosilicate glass, Soda lime glass, Fused silica (quartz), Sapphire, Non-alkaline glass.

Ultra-Thin Substrate Compatibility:

Support for substrates as thin as 50µm, enabling integration into compact and cutting-edge devices.

High Aspect Ratios:

Achievable aspect ratios up to 1:10, supporting high-density interconnections for advanced electronic applications.

Innovative TGV & BGV Fabrication:

Beyond TGV, we also fabricate blind glass vias (BGV), expanding the possibilities for your projects.

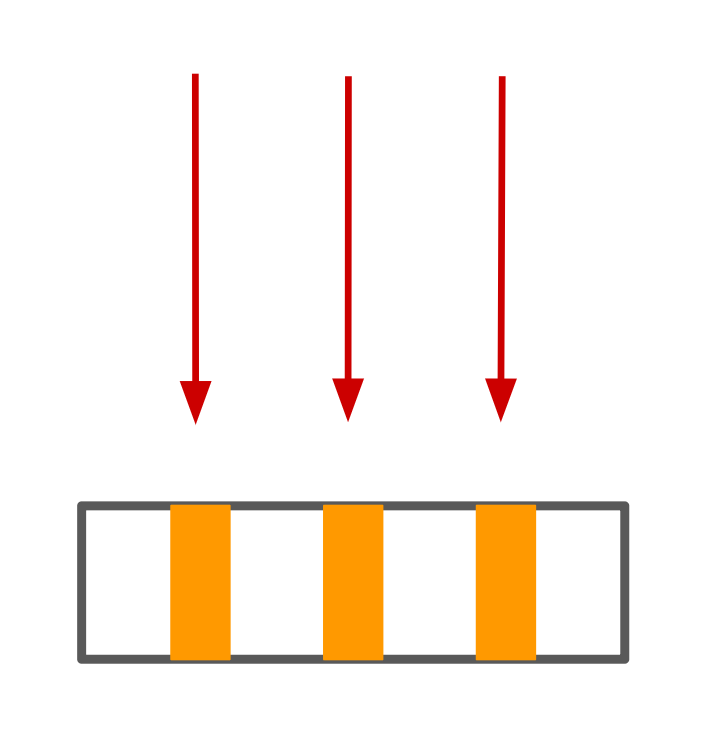

Our TGV (Through Glass Via) Fabrication process offers advanced glass PCB technology, enabling precise interconnects for high-performance electronic applications with unparalleled thermal stability and miniaturization benefits.

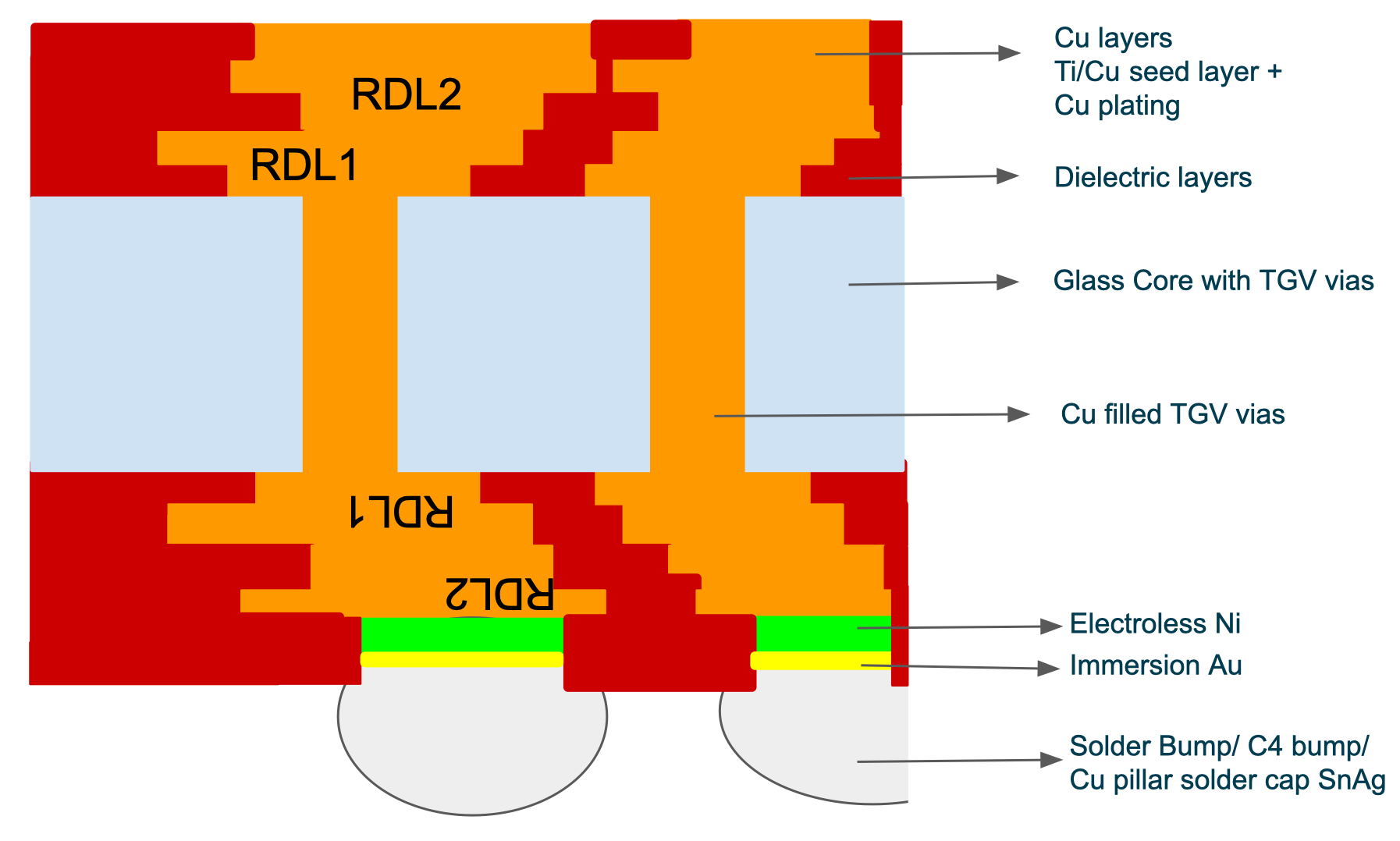

Cu filled (TGV) vias

We provide Through-Glass Vias (TGV) Copper filling and metallization services, utilizing advanced electroplating techniques to achieve high-quality results. The process begins with the deposition of a Titanium/Copper (Ti/Cu) seed layer within the vias. This crucial step ensures a solid foundation for the subsequent Copper (Cu) electroplating, allowing for either conformal coatings or complete, void-free via fills.

TGV Types

Completely filled Via

Conformal Via

Low resistance metal TGV

High via yield > 95%

We also provide other related services such as glass thinning using wet etching, Cu CMP, optical level polishing using CMP, Anodic bonding with Silicon wafers, thin film metallization, etc.

RDL(Redistributed Layers) for TGV glass substrate

Explore our cutting-edge both-side/ double side Redistribution Layer (RDL) technology designed for Through-Glass Via (TGV) substrates.

Find more information here.

Applications:

2.5D & 3D packaging

MEMS

RF devices (RF MEMS switches)

High-performance computing

Display

Optoelectronics

Glass interposer

Cell culture

Wafer-level optics

Microfluidics

Biomedical

Shadow mask: an alternative to metal masks

LED lights for better thermal management